Machinery for BSF Chitosan and Oil Production

As businesses explore the potential of establishing production facilities focused on oil and chitin extraction, it becomes crucial to understand the additional systems and machinery required for these processes.

Oil Extraction:

The equipment needed for oil extraction from BSF larvae is relatively standard. However, it’s important to note that the oil percentage obtained from the dry larvae weight can vary significantly depending on the type and composition of the organic waste used. Generally ranging between 20% to 50%, oil extraction requires efficient equipment for optimal results.

Chitosan Extraction:

Chitosan extraction, derived from BSF Chitin, involves a more complex process. The extraction and chemical processing of chitosan demand requires specialized machinery and know-how. Considering the intricacies of chitosan production, it is advisable for businesses to explore licensing this specific knowledge from third parties to ensure a smooth and successful extraction process.

Differences in Production Facilities:

Establishing a production facility focused on oil, chitin, and frass production requires careful consideration of the specific needs of each product. A key factor is the differentiation between an oil-rich BSF line and a high-Chitin BSF line. The egg-to-harvest cycle significantly differs between these lines, necessitating separate production lines for optimal results. This distinction in production lines can impact costs, requiring investment in different equipment and processes tailored to each product.

Yield from Larvae and Organic Waste:

Understanding the yield from each ton of larvae and the corresponding organic waste is crucial for efficient production. The oil yield varies between 20% – 50% of the dry larvae weight, depending on the type and composition of organic waste. Chitin extraction, on the other hand, yields 75% or more of the dry larvae weight, requiring a longer growth period.

The extraction of chitosan from Black Soldier Fly (BSF) larvae

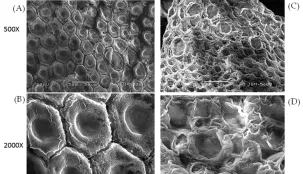

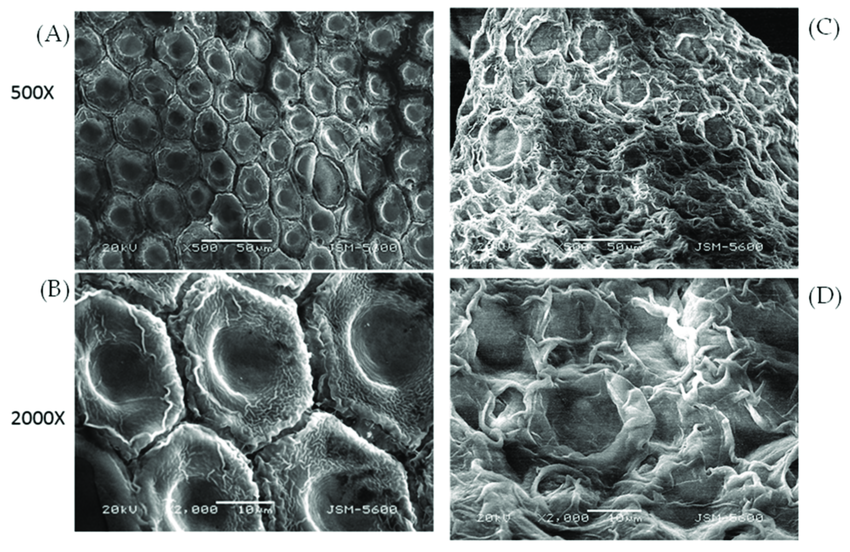

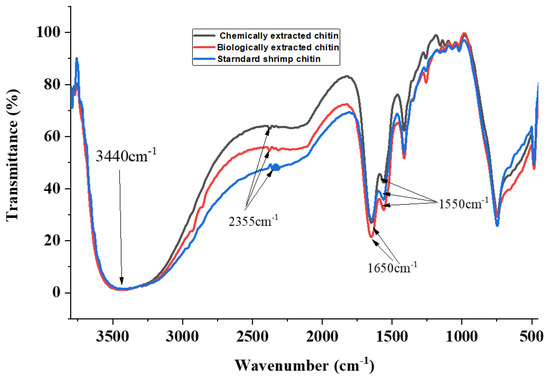

Involves a multi-step methodology. The chitin extraction process includes pre-treatment, demineralization, and deproteinization. The pre-treatment phase involves cleaning the raw material with water and detergent, oven-drying at 105°C, and grinding into fine particles. Demineralization is achieved by treating BSF samples with 1.5 M HCL for 2 hours at 25°C. The acidic treatment breaks down minerals into water-soluble salts. After filtration, the samples are washed with deionized water to remove the soluble mineral salts. The demineralization efficiency (DME) is evaluated by comparing ash content before and after treatment.

Deproteinization

The next step, involves a 2-hour treatment with a 2 M NaOH solution at 80°C. The samples are filtered and washed with deionized water to remove proteins. The efficiency of deproteinization (DPE) is determined by analyzing protein content before and after the base treatment.

After demineralization and deproteinization, the wet sample is dried overnight at 105°C. Analyses for ash content or protein content are conducted accordingly. During processing, the amount of deionized water used and the sample’s pH after washing are recorded. The overall yield, as well as yields after each process step, are calculated by dividing process output by input dry weights. The chitin yield is estimated by dividing the output (dried sample after deproteinization) by the input dry weights, assuming that only chitin remains after demineralization and deproteinization.

Protein Extraction and Value:

Protein extraction is a significant consideration in the production process. After oil extraction, approximately 50% protein content can be retained with the proper genetics and organic waste composition. However, Chitin extraction results in marginal protein left, emphasizing the need for strategic planning to maximize protein value in the overall production process.

Impact of Waste Input on Production Focus:

Choosing to focus initially on oil and chitin will have implications for the quality and type of waste needed as input. Different products require specific organic waste compositions and processing methods. Understanding these variations is vital for optimizing production efficiency and ensuring the highest quality output.

The production of oil, chitin, and frass from BSF larvae offers a promising avenue for sustainable waste management and the generation of valuable products. However, it requires careful consideration of machinery, processes, and waste inputs tailored to the specific requirements of each product. By understanding the complexities involved, businesses can make informed decisions and establish production facilities that maximize the potential of Black Soldier Fly larvae oil in the circular economy.

For more information about:

Insect bioconversion of waste, please contact us at the Insect school. https://www.insectschool.com/

Turnkey insect farms – https://www.insectengineers.com/bsfturnkey/production

If you would like to book BSF industry keynote speaker Bob Holtermans for your event – https://www.insectengineers.com/about-us/speaker-bobholtermans