Bio-Methane Potential of Insect Frass

Anaerobic Digestion

Anaerobic digestion offers an intriguing waste treatment option. It produces bio-methane, which can serve as biofuel or an energy source for electricity and heat production. This energy can then support insect production facilities, such as breeding.

Frass Definition

Frass refers to a mixture that includes excrements from farmed insects, the feeding substrate, parts of farmed insects, and dead eggs. According to the European Commission Regulation (EU)2021/1925, it contains no more than 5% dead farmed insects by volume and 3% by weight.

Insect Frass Samples

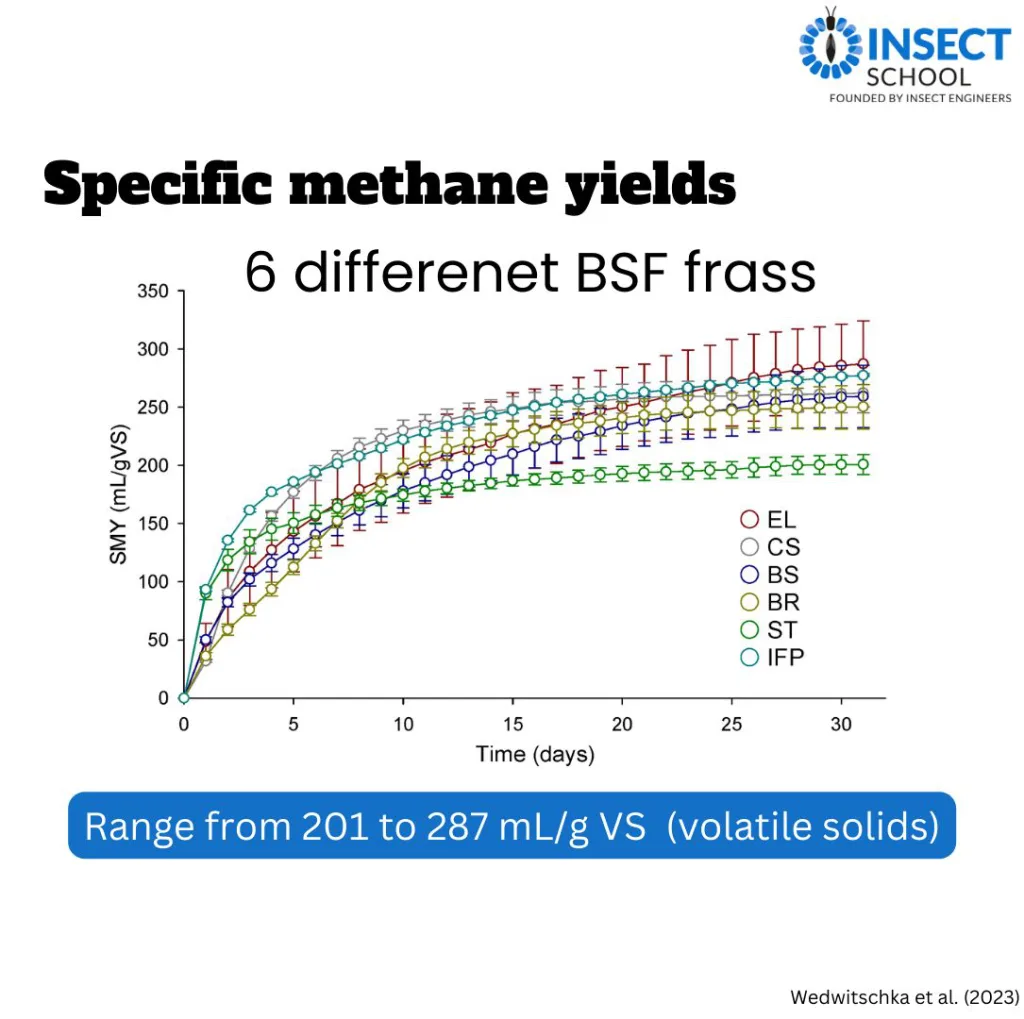

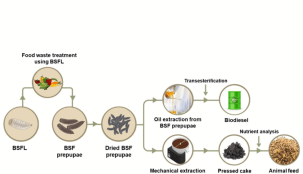

Researchers tested six insect frass samples. The larvae in these samples consumed various feeds: 1) corn silage (CS), 2) brewers spent grain (BS), 3) thin stillage from bioethanol production (ST), 4) aquatic plants from the Elodea genus (water-seeds, EL), 5) wheat bran (BR), and 6) a pilot plant with cereal grains (IF_PP).

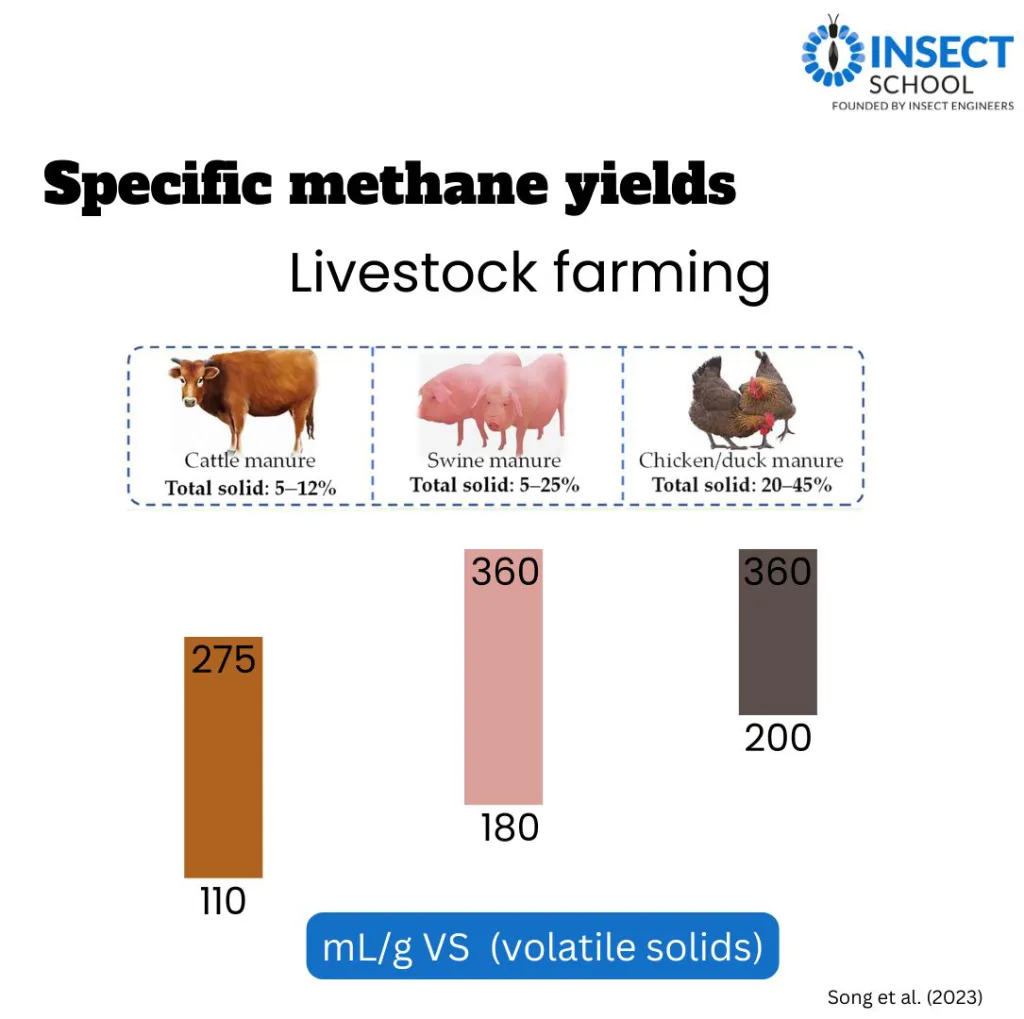

Methane Yield Comparison

The specific methane yield (SMY) of the tested frass varied between 201 to 287 mL/g VS. This range is similar to residues from livestock farming. For instance, cattle manure yields 110-275 mL/g VS, pig manure produces 180-360 mL/g VS, and chicken manure results in 200-360 mL/g VS. Water-seeds fed BSF larvae frass had the highest methane yield. It was followed by frass from cereal grains, corn silage, brewers spent grain, and wheat bran.

Biogas Production in Germany

Black Soldier Fly larvae frass, when fed with cereal grains, achieved a specific methane yield of about 140 m3/ton fresh matter. In comparison, corn silage, a common biogas substrate, produces 110 m3/t fresh matter. Wedwitschka et al. (2023) noted that corn silage is a primary biogas substrate in German agricultural biogas plants, second only to cattle manure. However, in 2021 and 2022, droughts led to a corn silage shortage in some German regions. This scarcity affected dairy farming and some biogas plants, leading to decreased annual energy production and profitability. In the coming years, alternative residues like BSF frass might replace corn silage in biogas plants, especially during low substrate supply years.

Sanitization in Europe

Before using insect frass as a soil amendment in agriculture, Europe mandates proper sanitization. The frass must undergo treatment at 70 degrees Celsius for an hour. Potential sanitization methods include heating, pelleting, or extruding the frass. However, these processes consume significant energy. Wedwitschka et al. (2023) suggest that a thermophilic (~38 Celsius) digester system might provide an efficient sanitization method for BSF frass, even without a subsequent composting stage.